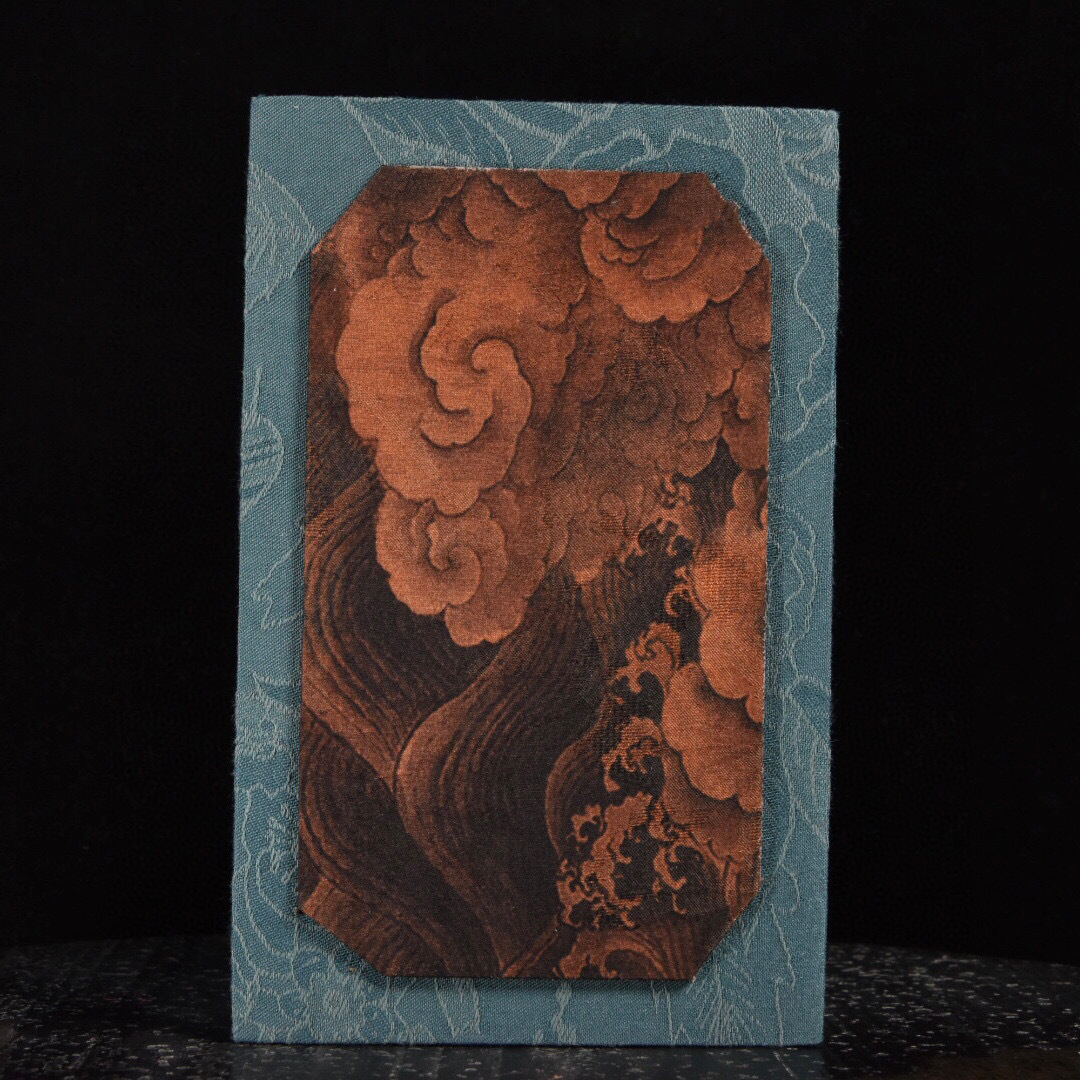

【蔵友館蔵品・寿山石・烏鴉皮・田黄石・細密彫・鳳凰戲牡丹紋・印章・箱付】・希少珍品・置物・賞物・中国時代美術

(税込) 送料込み

商品の説明

商品説明

| 【蔵友館蔵品・寿山石・烏鴉皮・田黄石・細密彫・鳳凰戲牡丹紋・印章・箱付】・希少珍品・置物・賞物・中国時代美術 |

| ||||

|

| ||||

|

| ||||

|

| ||||

|

55200円【蔵友館蔵品・寿山石・烏鴉皮・田黄石・細密彫・鳳凰戲牡丹紋・印章・箱付】・希少珍品・置物・賞物・中国時代美術事務、店舗用品文房具

商品の情報

カテゴリー

配送料の負担

送料込み(出品者負担)配送の方法

ゆうゆうメルカリ便発送元の地域

宮城県発送までの日数

1~2日で発送メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています